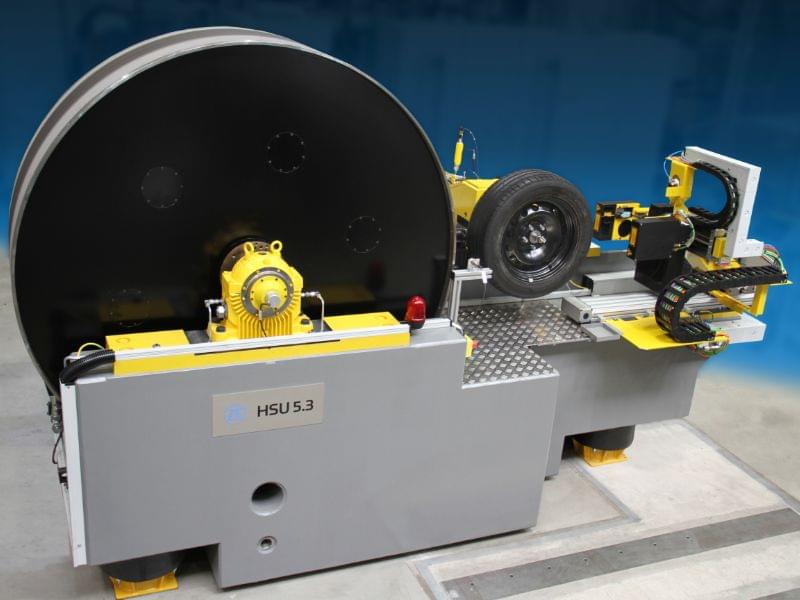

Smithers recently

invested in the ZF HSU 5.3 machine to add to our already comprehensive list of tire testing capabilities. In this short Q&A, learn about high-speed uniformity (HSU) testing, the machine’s benefits and how it solves technical challenges in this Q&A from Matt Kent, Technical Director at the Tire & Wheel Testing Lab located in Ravenna, Ohio.

Why might a client require high-speed uniformity testing?

A client will come to us when they are looking to investigate noise vibration and harshness (NVH) complaints. These complaints often stem from tire related resonances related to tire design and quality build issues. In many cases, uniformity issues are confused with tire balance issues by the consumer. If the issue is non-uniformity, then rebalancing your tires will not mitigate the vibration because it is a due force variation and not a mass imbalance. Our HSU machine can also perform other types of testing that are in high demand in the tire industry, such as cleat impact, flat spot, and revolutions per kilometer (RPK) testing.

What challenges can the data help to solve?

The HSU reports that we generate from transient testing provides our clients with a full spectrum analysis across the entire speed range. This is a more comprehensive approach compared to the typical single-speed or multi-speed HSU tests and helps us solve customers’ uniformity issues.

As

electric vehicle development continues at a rapid pace, new questions have been generated as it relates to tires. Higher vehicle weights can cause flat spotting issues, which need to be understood and resolved. In addition, without the traditional engine noise or driveline vibrations, consumers will notice tire generated noise and vibrations much more frequently. This creates even more of an emphasis on understanding how a tire will perform on electric vehicles.

What other benefits does our HSU machine provide to the industry?

Our lab committed to the purchase of the HSU machine based on its proven design, useability, and data analysis software. The HSU machine is built on its own seismic mass, which mechanically raises the machine’s natural resonance above 300Hz. When this occurs, it removes vibrational influence from the machine in the area of interest relative to the tire.

How can HSU data be used with tire modeling?

The HSU machine is the perfect machine for high-speed cleat impact testing, due to its robust design and high natural frequency. Cleat data provides a “signature” of an impact; almost like a fingerprint. All tire sizes and designs can be unique. This type of testing is critical when developing and building tire models.

Adding HSU with cleat impact capabilities coupled with our existing force and moment, tire footprint and stiffness capabilities provide a full data set that can be provided to data fitters and OEMs.

How can we help?

Smithers offers additional capabilities to support HSU testing, such as

ovens and fixtures for flat spot testing. Our Tire and Wheel lab offers a broad range of testing services such as, measuring

performance,

durability, rolling resistance, and other characteristics of passenger car, light truck, agricultural, truck, off-the-road (OTR), and specialty tires.

To learn more about our HSU machine or to discuss a testing project, contact Matt Kent, Technical Director, Tire and Wheel Testing at

mkent@smithers.com.